-40%

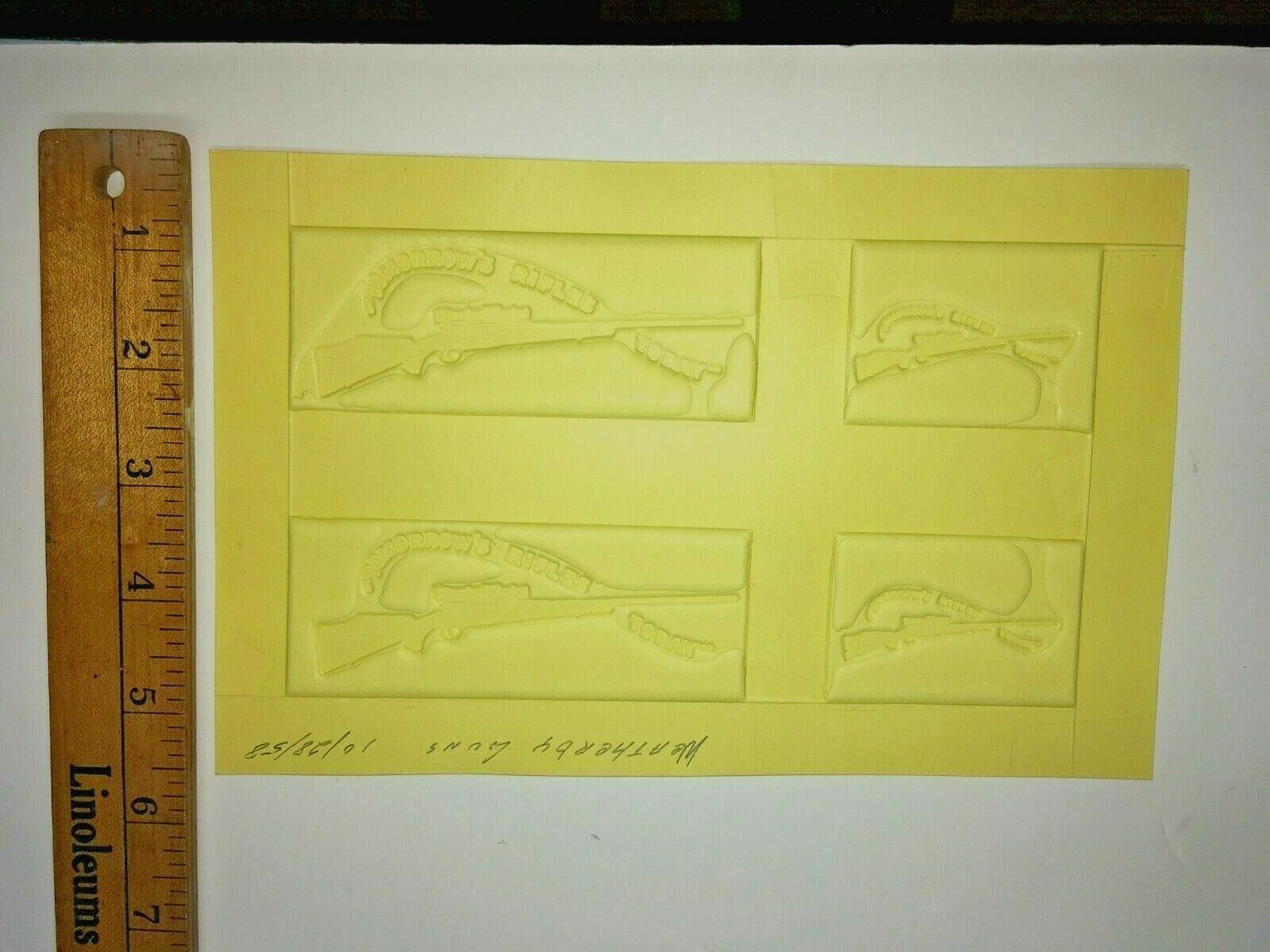

ONE VERY COOL 1958 Vintage Print Ad Mat Weatherby Guns TOMORROWS RIFLES TODAY

$ 5.28

- Description

- Size Guide

Description

Very Cool - ONE AD MAT sheet from 1958 - "TOMORROW'S RIFLES TODAY" for Weatherby guns, would be cool framed. See up close photos for details and read below wikipedia info on ad mats. The first photo shows the one sheet you will receive, the other photos show the seperate ads up close.**The photos are enhanced to see detail.

I will be listing several more different ad mats fishing, hunting, boating, sports from 1940s and 1950s, see additional listings. These are very cool vintage cardboard embossed ad mats called dry matrix flongs for stereotyping. These were used to make a metal plate to print an ad in the 1940s and 50s. A

ll that I list are advertising different items and are unused Dry matrix flongs to make stereotypes.

From the internet

for more information, once these dry mat flongs for stereotypes were used, you could not use them again, :

"In printing, a

stereotype

,

stereoplate

or simply a

stereo

, is a solid plate of

type metal

, cast from a

papier-mâché

or plaster, or dry matrix mould taken from the surface of a

forme

of type.

The mould was known as a

flong

.

In

relief printing

, a

flong

is a temporary negative mould made of a

forme

of set type, in order to cast a metal

stereotype

(or "stereo") which can be used in a

rotary press

, or in

letterpress printing

after the

type

has been broken down for re-use. The process is called

stereotyping

.

Dry mat, or dry matrix process. Here there is no need to beat the matrix into the page of type, but simple pressure is enough. The pressures needed are quite high

and effectively require a hydraulic press. By 1946, the dry mat process had completely taken over in newspaper publishing in the United States

Making the stereotype

After moulding the stereotype it is carefully removed from the mould. If the locking the flong into a moulding box, the box was pivoted so that the flong was in the vertical plane, and liquid type metal was poured into the mould. For newspapers these moulds were cylindrical in shape. This quickly cooled, and the mould was opened to remove the stereo. The stereo might be cooled further. The back of the stereo was then shaved, to reduce it to the required thickness for the press. The stereo was also trimmed and had the edges bevelled (to enable the stereo to be camped into place). The stereos where then clamped into place on the printing cylinder, and the print run began.

Type metal is an alloy of

lead

,

tin

, and

antimony

. Lead on its own makes type too soft to be of use. Tin was added to lead to make it harder, but the results were unsatisfactory. It was found that adding both tin and antimony led to type that was hard, resistant to wear and to distortion under pressure, and gave sharp reproductions.

The lowest solidification point for a liquid lead, antimony, and tin alloy occurs when the antimony content is twelve percent, known as the

eutectic alloy

. Keeping the antimony content close to twelve percent ensured the lowest possible melting point, important for slug-casting machines which melted an alloy ingot for casting the slugs. Low melting point is also important for the metal used for stereos as very high temperatures would damage the flongs. The type metal used for stereos was slightly different from the type metal used for foundry type, slug casting machines like the

Linotype machine

, individual letter casting machines as in the

Monotype machine

, or the metal used for backing electrotypes. While increasing the antimony content increases hardness, the tin content must be increased in proportion to achieve this.